Case P1: High Rate Ion-beam Sputter Deposition

Ion-beam sputter deposition (IBSD) has increasingly become a preferred modality when thin-film quality, reproducibility and controllability are of primary importance. In this example we examine what deposition rates can be expected from an ion source that is capable of supplying an ion current of 1200 mA with an ion energy of 1500 eV.

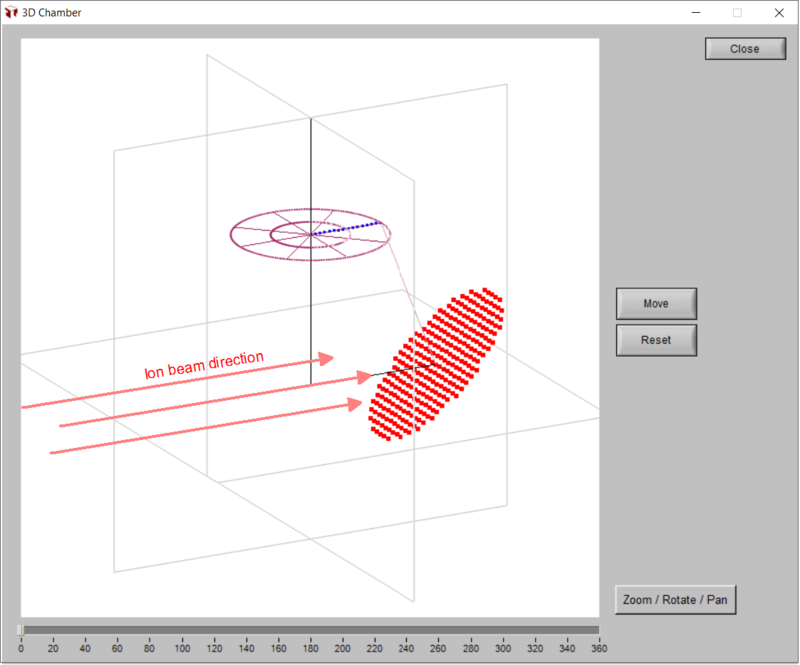

First, we study a high-deposition-rate configuration: a single-rotation substrate fixture that is positioned in a common fashion, relative to the target. The ion beam strikes the target at a 45 degree angle; the plume function of the sputtered particles is assumed to take the most commonly observed form under directed ion bombardment.

To obtain the deposition rate of a material one needs to enter, in the Deposition Rate Calculator dialogue of V-Grade 5S Pro, three physical quantities of the material: molecular mass, density and sputtering yield. In addition, the ion beam energy and ion current must be specified. Here we compute the deposition rates of three different materials: silicon, aluminum and silver, all under the full power of the ion source. The results are summarized below.

Material: Si

Molecular mass: 28.09 u

Density: 2.33 g/cm^3

Sputtering yield: 1.63

Ion energy: 1500 eV

Ion current: 1200 mA

Deposition rate: 24.0 nm/min

Material: Al

Molecular mass: 26.98 u

Density: 2.7 g/cm^3

Sputtering yield: 2.71

Ion energy: 1500 eV

Ion current: 1200 mA

Deposition rate: 33.1 nm/min

Material: Ag

Molecular mass: 107.87 u

Density: 10.49 g/cm^3

Sputtering yield: 5.57

Ion energy: 1500 eV

Ion current: 1200 mA

Deposition rate: 70.0 nm/min

These calculated deposition rates are in agreement with what are provided by a vendor for a commercial IBSD system that employs such an ion source.

With V-Grade 5S Pro we can, with similar ease as the above cases, calculate the deposition rates of various materials in processes involving planetary-rotation of substrates. For example, if silicon dioxide (SiO2) is deposited (with the same ion source) on a 330-mm-diameter disk in a four-planet fixture, V-Grade 5S Pro can guide you to an arrangement that yields the following result:

Material: SiO2

Fixture: 4 planets of 330 mm in diameter

Ion energy: 1500 eV

Ion current: 1200 mA

Deposition rate: 22 nm/min

Thickness uniformity: 0.18% across the planets

Vapor capture: 23.0%

Correction mask: none

Modeling details of this planetary-rotation IBSD will be given in a separate case study.

© 2025 Tin Model LLC. All rights reserved.