Newsletter issued in May 2018

Modulated-transit for High-Precision Coating, Part I

Modulated-transit is a sputter-deposition technique that has been successfully applied to high-precision coating for optics. Reported by Spiller et al (2001) for achieving precision control of thickness in EUV optics, the sweep speed (or the sputtering power) is modulated when substrates transit through the region where material vapor is concentrated.

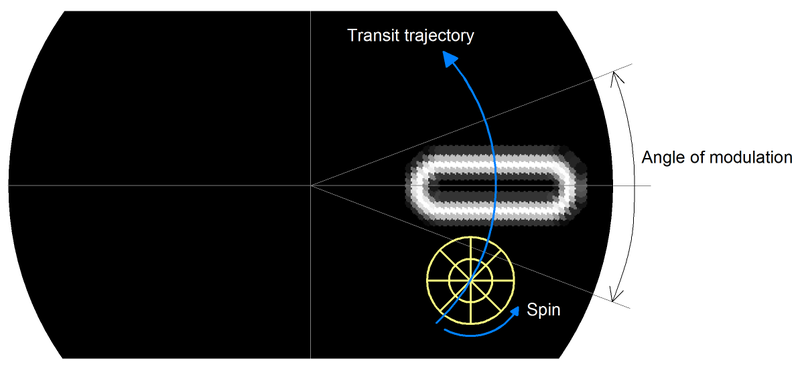

TinModel's V-Grade 5S modeling tool is ideally suited for studies and optimization of this technique. Here we show how the modulated-transit technique (power modulation) can be employed to maintain tight thickness uniformity over a flat substrate in the life cycle of a sputtering target. (In part II and III we will show the impact of chimneys and coating of curved surfaces.) It is well know that the vapor plume of a sputtering target changes its distribution through its life cycle due to erosion. In a sputter-deposition process of the geometry blow, either the angle of modulation or the depth of modulation must be adjusted to account for the change in vapor plume.

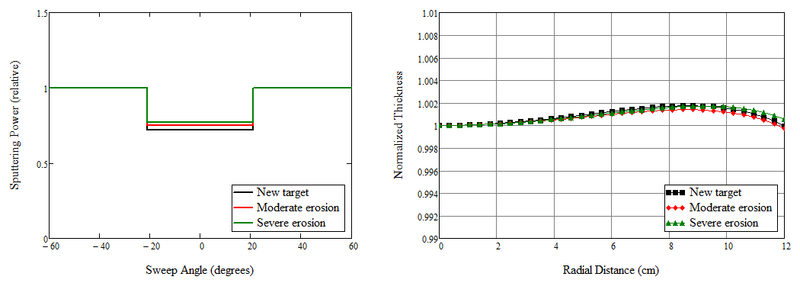

V-Grade 5S helps you to quickly determine the appropriate modulation profiles under various plume distributions. The software models a vapor plume with a three-term polynomial of the cosine, whose coefficients can be determined through fitting of experimental data. The difference between a new and an eroded target can usually be described adequately with just two terms.

The figure below shows the modulation profiles of sputtering power for a target (Si or similar material) for three different erosion states. The substrate is 24 cm in diameter and is coated with a rectangular sputtering target in the geometry shown in the diagram above. The sputtering power is reduced in the sweep range between -21 and 21 degrees; for new, moderately eroded and severely eroded targets the modulation depths are 72%, 75.5% and 77%, respectively. With these power modulation profiles, the thickness uniformity of the deposited material is better than +/- 0.1% at all times.

For tight thickness controls like this example, even minor changes, such as the use of chimneys, can upset the outcome drastically and require modifications to the modulation profile. V-Grade 5S enables you to study these effects and predict results at ease. Please contact Tin Model for further information.

© 2018 Tin Model LLC, 2285 Massachusetts Ave.

Cambridge, Massachusetts 02140, U.S.A.

Phone: (857)498-9723

www.tinmodel.com