Newsletter issued in July 2017

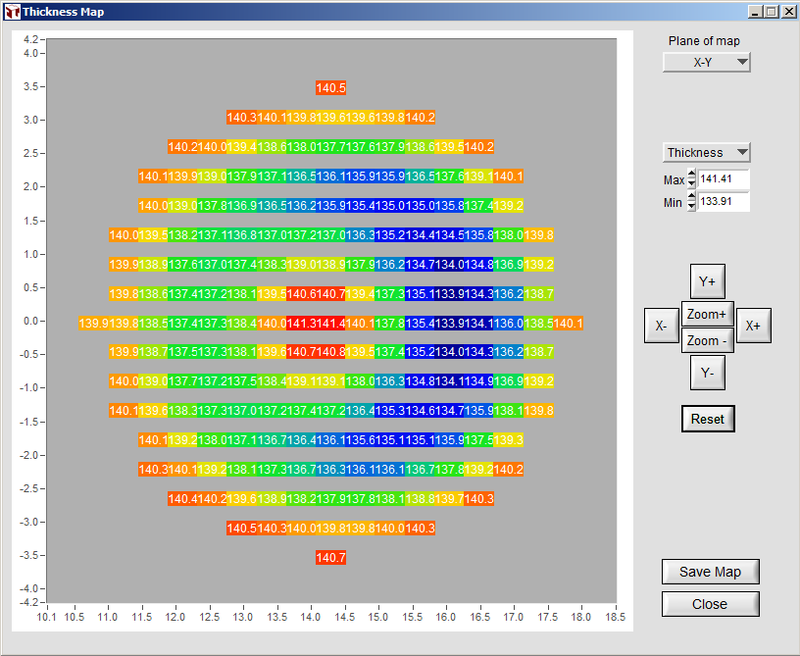

Value-labeled Thickness Map etc.

1. Released: A Virtual PVD Coating System by Tin Model LLC

Manufacturers of PVD thin-film materials and equipment have typically relied on empirical data and trial-and-error in approaching their jobs. A new tool now allows PVD engineers to achieve the best quality of work at a fraction of the time needed in the traditional way. The tool is our numerical modeling software, V-Grade 5S, recently released by Tin Model LLC.

With V-Grade 5S engineers can easily prove their innovative ideas, which would otherwise be too costly to test out through trial runs.

V-Grade 5S provides: 1) Thickness distribution on your parts, flat or curved; 2) Absolute thickness for every gram of material consumed, sputtered or evaporated; 3) Statistics on how particles strike the surfaces to be coated; 3) Material collection efficiency in percentage; 4) How positioning and angling of your source affects coating results; 5) Consequence of target erosion; 6) How gas-phase collisions affect thickness distribution; 7) Best design and placement of correction masks; 8) Automated optimization of correction masks; and a lot more.

Farewell to the time-consuming and costly trial runs in PVD coating. You will find that your coating system is much more capable than it was assumed to be.

2. Tin Model LLC Adds Value-labeled Thickness Maps to V-Grade 5S

To make its PVD modeling tool more user-friendly, Tin Model added false-colored and value-labeled maps to the output of V-Grade 5S. The image above shows the thickness distribution on an aspherical lens surface. (The asymmetry in thickness can be easily eliminated through pivoting the surface. Please visit http://www.tinmodel.com/Case-6.html for more details.)

For more information regarding V-Grade 5 series PVD tools, please visit www.tinmodel.com.

© 2017 Tin Model LLC, 2285 Massachusetts Ave., Suite 203

Cambridge, Massachusetts 02140, U.S.A.

Phone: (857)498-9723