NEWSLETTER October 2023

Important Considerations for Correction Masks

Copyright © 2023 Tin Model LLC. All rights reserved.

-- your partner in PVD engineering & innovation

For thickness uniformity, correction masks (shadow masks) are frequently employed in physical vapor deposition (PVD) processes, whether they are based on evaporation, magnetron sputtering or ion-beam sputtering.

The following are a few common considerations in designing and installing correction masks.

1. Masking and Other Optimization

Correction masks are best employed in conjunction with other optimization, such as adjustments of the vapor-source location. The benefits include simpler masks and reproducibility.

2. Preservation of Vapor

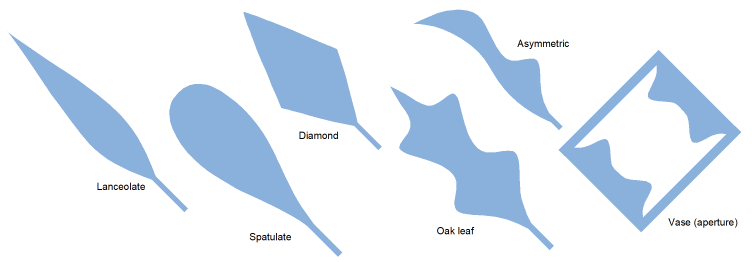

While achieving the uniformity specs, a correction mask should obstruct as little vapor as possible to minimize the impact on deposition rates. An advanced auto-shaping algorithm (V-Grade 5S) is able to find solutions that optimize uniformity at the lowest cost of deposition rate. Examples of vapor-preserving masking …

3. Vapor Plume Differences

In a multi-material production, the performance of a mask should be evaluated for all the materials because they can exhibit different vapor plumes. This can also happen to the same material through the life of a sputtering target. A discussion of changing plume function …

4. Installation Provision

A mask design must include its mounting hardware: even a narrow mounting rod can significantly alter the final thickness uniformity in precision coating. Mounting handle is an integral part of mask design with V-Grade 5S series software …

5. Minimize Contamination

Whenever possible a mask should be positioned so that flake-off debris do not contaminate the substrates or the vapor source. This improves product quality and reduces the need of maintenance. Example of an offset mask …

6. Stability

Some mask designs may look good in simulation but they require installing precision to an unreasonable degree. These masks are unlikely to produce uniform and stable thickness distributions.

7. Separability

For multi-source chambers there are ways to installing masks so that a mask assert correction for one vapor source only -- no cross-talk among mask-source paring. Example of mask decoupling …

8. Rotating or static

Sometimes rotating masks are unavoidable. And there are cases rotating masks are unnecessary, their use adds complexity, cost and other potential drawbacks. More on rotating masks …

V-Grade 5S series modeling software allows you to design and compare masks with ease. Every aspects listed above can be examined before production and final approval. Please contact us at Tin Model for further information -- we will be happy to send a demo to you.