V-Grade 5 is available for trials and licensing!

Tin Model proudly introduces V-Grade 5, a virtual PVD coater for engineers and researchers who operate or design evaporation-source PVD (physical vapor deposition) systems for thin-film manufacturing. Given the tooling and fixturing, i.e. substrate motion and geometric configuration, of a coating apparatus the numerical tool simulates its coating processes in high precision and realism. As a validation tool, V-Grade 5 helps you to prove a design concept and optimize a new configuration. For thin-film manufacturing, V-Grade 5 allows you to greatly reduce the resources necessary in trial runs and achieve the best possible result for a coating job.

V-Grade 5 is now available for trials and licensing. Please visit Products for more details.

© 2024 Tin Model LLC. All rights reserved.

- How to obtain symmetric thickness distribution on lenses?

- How to achieve thickness uniformity without correction masks?

- What is the technique of "Terracing"?

Answers in "Get the Most out of Your Coaters"

HOT TOPICS

- How single-axis rotation and planetary rotation compare in sputter deposition?

- How erosion of a sputtering target affects thickness uniformity?

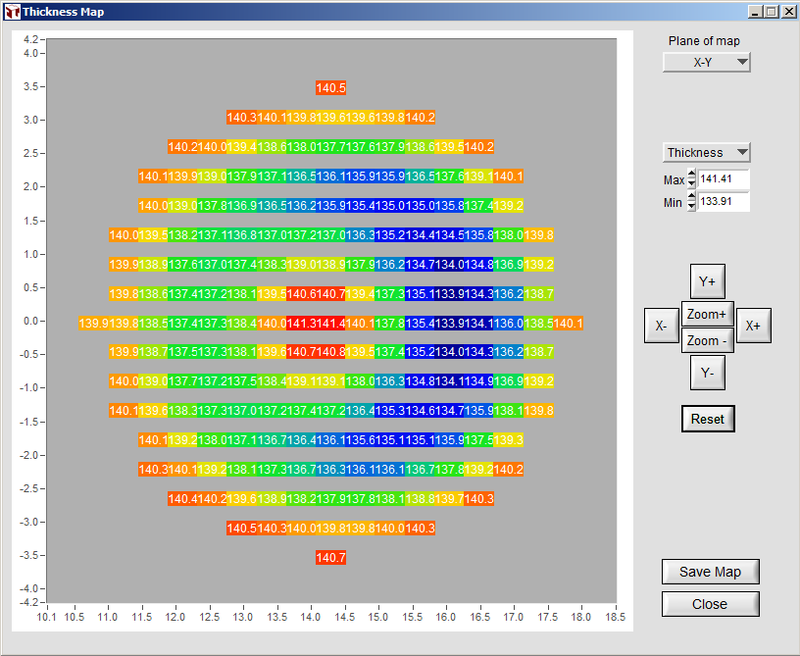

New: Value-labeled thickness maps added to V-Grade 5S

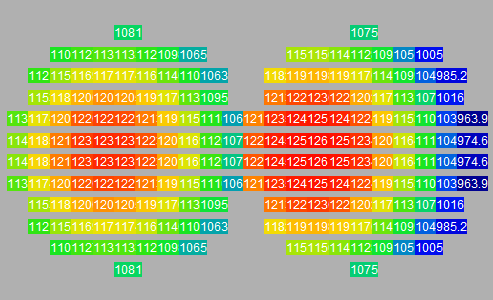

To make our PVD modeling tools more user friendly, we recently added false-colored and value-labeled thickness maps to the computational output of V-Grade 5S. Not only you can quickly grasp the thickness distribution through color, but also you can zoom in to examine the thickness value for each sampling point of a surface.

The image above shows the thickness distribution on an aspherical lens surface. The labeled are absolute thickness values: nm per gram of source material consumed. (The asymmetry in thickness can be eliminated through mounting the lens with a pivoting angle. Please see case studies for details.)

New: Vapor Plume Fitting to Experimental Data

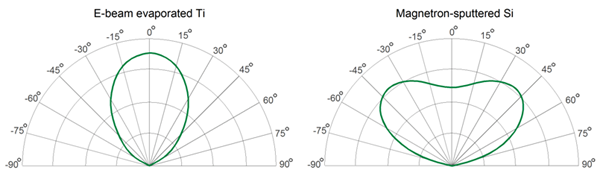

Tin Model proudly announces the release of V-Grade 5S / Option P, which includes the much-anticipated feature of vapor-plume fitting to experimental data, whether they are from evaporation or sputter-deposition processes.

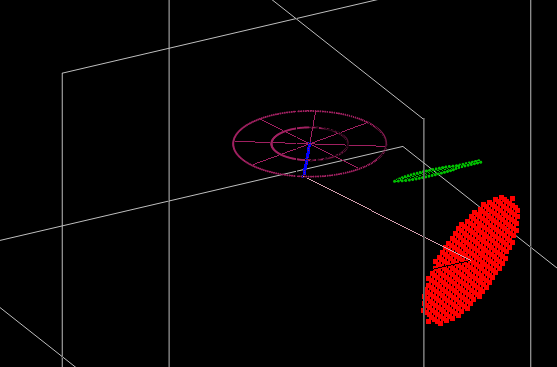

Tin Model's modeling software treats plume functions with a 3-term polynomial of the cosine: it is capable of describing all experimental observed plume functions, including the evolution of vapor plumes associated with aging of sputtering targets. The input accepts measured thickness data from stationary or rotational deposition runs.

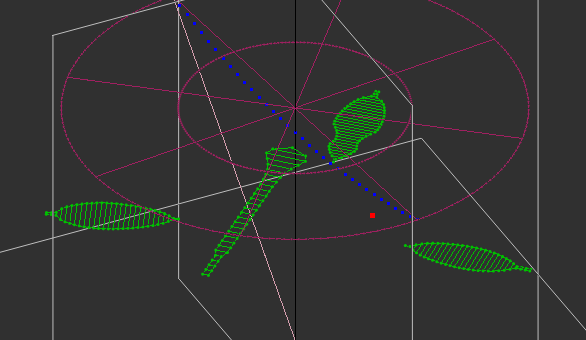

With Option P, engineers can characterize PVD sources to a great precision, which, in turn, allows for reliable prediction and control of coating results. Recent experiments have demonstrated the effectiveness of such an approach. The vapor plume distributions shown above were obtained through fitting the polynomials of the cosine, with Option P, to measured thickness values of Ti (evaporated) and Si (sputter-deposited) thin films on stationary and rotating substrates, respectively. The focused vapor plume is typical of electron-beam evaporation sources while the heart-shaped plume is typical of magnetron-sputtering sources.

Please contact us, [email protected], for more information or requesting an upgrade.

New Release: V-Grade 5S Plus

Tin Model LLC proudly announces the release of V-Grade 5S Plus -- a suite of PVD modeling tools with a focus on sputtered thin films.

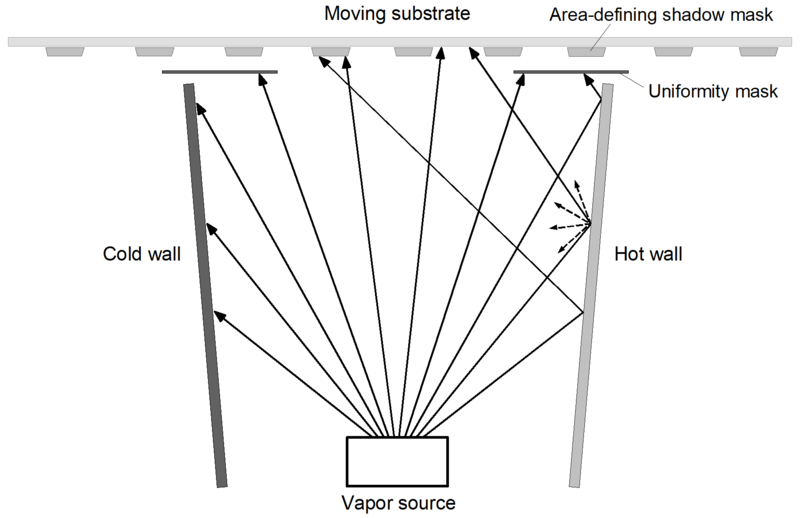

V-Grade 5S Plus expands the realm of PVD modeling to include such physical phenomena as plasma-substrate interaction and non-unity sticking of vapor particles. Also new in V-Grade 5S Plus are modeling of linear substrate motion and an advanced thickness control technique: the modulated transit. The computation speed of V-Grade 5S Plus is nearly tripled from our previous versions.

Bombardment of thin-film surfaces by energetic species (high-velocity neutrals, ions and electrons) is present in nearly all sputter-deposition processes. Sputter-deposited thin-film materials often owe their desirable properties, i.e. density, hardness and crystallinity, to the bombardment. Some unbalanced magnetrons and High Power Impulse Magnetron Sputtering (HiPIMS) are specifically designed to harness the benefits of the bombardment. Quantifying the effects of such bombardment, however, is usually difficult, particularly when a complex geometry is present. With V-Grade 5S Plus, you can quantify these effects through the corrections they cause (which may be subtle in some cases) to film thickness distribution and to absolute thickness values.

V-Grade 5S Plus is constructed on the same platform as our previous releases. It's inherently versatile -- it can seamlessly handle vapor sources of various types and geometries, substrates from flats to arbitrary 3D surfaces, multiple shadow masks of arbitrary shapes and polarity. Its vapor-plume fitting function allows users to determine the plume function of a source from experimental data.

With V-Grade 5S Plus, you can predict the outcomes of PVD processes to ever greater accuracy. You will be able to optimize your processes with high efficiency and effectiveness. You can improve the quality of your products and maximize the yield of production. You can quickly prove your new concepts for thin-film manufacturing. All these are now possible through dispensing some computer time and mouse clicks.

Please visit Products to view a list of functions and features included in V-Grade 5S Plus.

September 25, 2018

February 15, 2018

July 14, 2017

As of September 2018 V-Grade 5 is superseded by V-Grade 5S. Tin Model still supports existing V-Grade 5 licenses. Users can upgrade to either V-Grade 5S or V-Grade 5S Plus.

Check it out: Tin Model is on YouTube

To better serve the PVD community and our customers, Tin Model has inaugurated its new YouTube channel: Tin Projects. We will use this channel as a venue to communicate with you about our products, to share knowledge and techniques on PVD, and to offer tutorials on our software tools. Please subscribe to the channel and stay updated!

June 16, 2019

New tutorial: Determine plume functions

A new tutorial has been placed on our YouTube channel: Tin Projects. It teaches how to use V-Grade 5S Plus to determine the plume functions of your vapor sources.

June 18, 2020

Tin Model proudly introduces our most advanced PVD engineering software product to date:

V-Grade 5S Pro

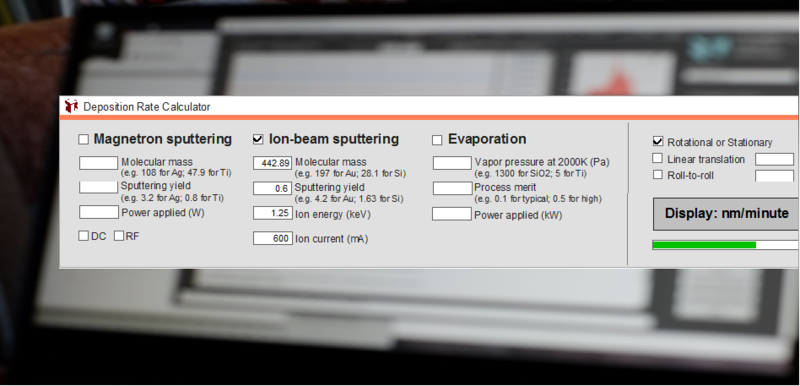

A new and major capability of this product is the prediction of deposition rates of any given material. It is simple and easy to use. All you need to provide is some material properties, plus the power applied to the source. The source can be magnetron-sputtering, ion-beam sputtering or evaporation type.

Be confident as you approach your next PVD project: V-Grade 5S Pro will help you determine what PVD tool is best for your manufacturing needs, how to optimize your existing equipment, and enable you to turn your innovative ideas to winning PVD processes.

V-Grade 5S Pro allows you to design and optimize your PVD processes with respect to:

Deposition rate - important for throughput

Vapor capture - efficient use of source material

Thickness uniformity - vital for technical specs

For as long as PVD has been a manufacturing method, the above 3 aspects are fundamental measures of a process. Never has it been easy to quantitatively analyze or predict them, much less to compute all 3 in one numerical tool. Now, V-Grade 5S Pro accomplishes just that. You can quickly and reliably know these 3 measures quantitatively for engineering choices such as source type, substrate movements, methods for achieving thickness uniformity, power supply requirements and so forth.

In addition, V-Grade 5S Pro provides valuable information for material-growth dynamics. This includes incident-angle statistics, plasma-substrate interaction (for unbalanced magnetron sources or HiPIMS), flux distribution of assistant ions and radiation heating, and much more.

We are confident that V-Grade 5S Pro will enable greatly improved efficiency and outcome of PVD engineering.

V-Grade 5S Pro is now available for licensing. Please contact us for a quote. We will be happy to provide a free demonstration version for evaluation.

April 8, 2021

NEW RELEASE: V-Grade 5S Pro

- deposition rates now at your fingertips

TIN MODEL LLC

Thin-film manufacturing processes are varied in their purposes and methods. Tin Model programs can be employed to simulate virtually all PVD processes known to exist.

"Get the most out of your ..." means achieving the best of your objectives, which may be different from one job to another.

Our latest release V-Grade 5S Pro is for a lot more than achieving thickness uniformity - it yields a comprehensive set of information that is essential for production planning and budgeting.

V-Grade 5S series programs are multi-facet modeling tools that can be used for solving a wide range of engineering and manufacturing problems.

A correction mask isn't always the only solution, or the best solution, to a thickness-uniformity problem. But there are situations in which correction masks are indispensable. Here is one example.

HIGHLIGHTS

For a limited time, Tin Model offers rapid-turnaround consulting service for businesses in need of a solution, within a short time frame, to some well-defined problems in thin-film manufacturing.

NEW IN PVD Original posting Aug 25, 2022; updated July 2023

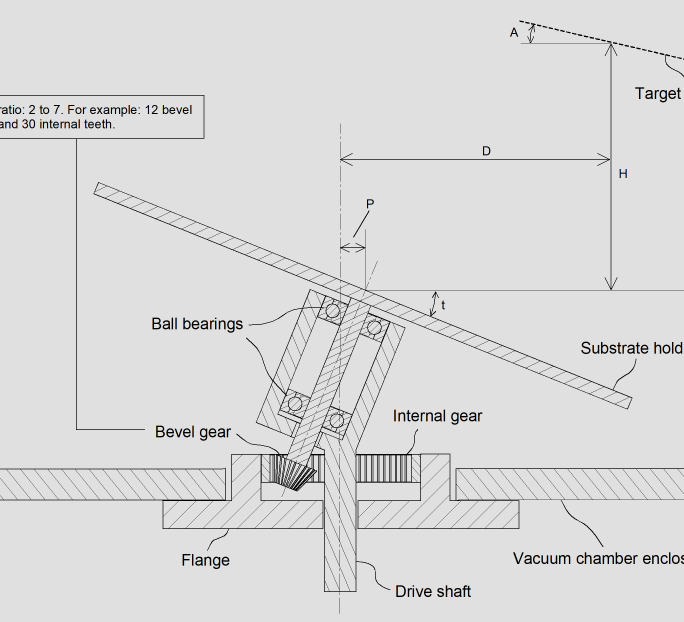

Large-area Uniformity That Holds

There are two problems in precision coating with commonly-known fixtures:

- In order to obtain uniformity we have to build a vacuum chamber that is much larger than a substrate holder to house a rotating fixtures, such as a planetary-rotation mechanism;

- When a sputtering target erodes or material changes, a hard-earned thickness uniformity drifts from specifications.

Tin Model is pleased to introduce an innovation that can simultaneously solve these two problems.

New - April 2023

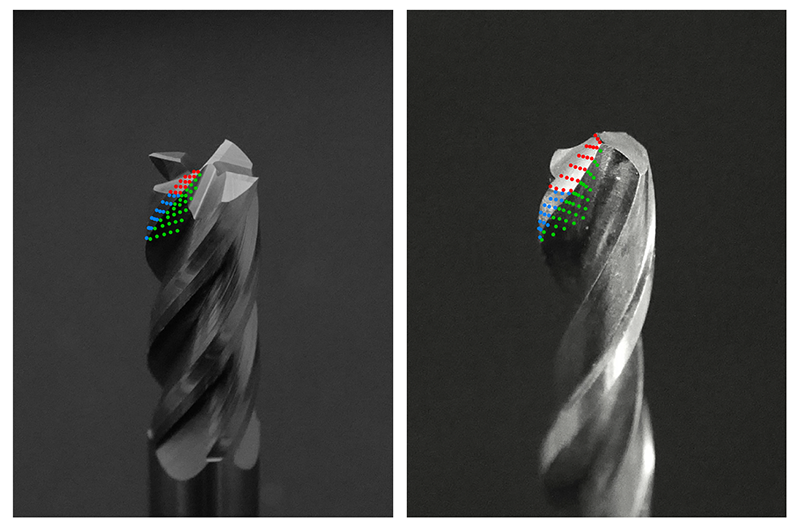

Engineering of Tribological Coatings gains a powerful weapon

Tin Model LLC introduces a new application package for the tribology PVD industry:

TCE: Tribology Coating Engineering

With this package, an engineer can quickly visualize, analyze and optimize a coating process for best physical properties of the deposited material, load uniformity and highest throughput.

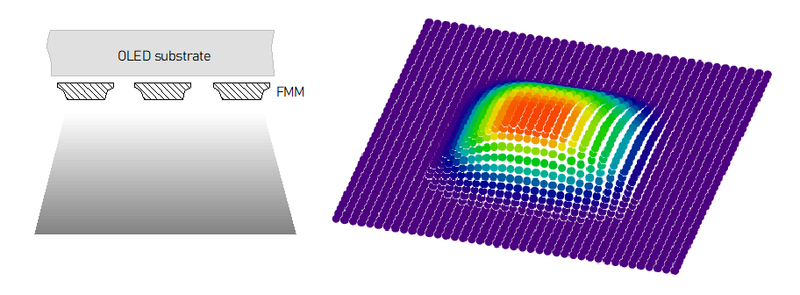

OLED (organic light-emitting diodes) displays have greatly expanded the needs for physical vapor deposition. A majority of OLED panels have been manufactured with the help of fine metal masks, or FMM, in forming pixel arrays of the light-emitting materials. Tin Model's V-Grade 5S series modeling software is ideally suited for engineering of OLED manufacturing processes. READ MORE

Notes on applications of V-Grade 5S, December 2023

Ascending Application of V-Grade 5S: OLED

Notes on Applications of V-Grade 5S, January 2024

Achieving Realism in PVD Modeling: Elements to Include

In workflows of PVD engineering and productions, numerical modeling plays increasingly important roles.

To achieve a satisfactory realism, a numerical model needs to include a number of elements that affect the vapor deposition process. Frequently, some of these elements are not addressed in modeling work. Such omissions can lead to predictions that are unrealistic or erroneous.

With suitable numerical tools and a judicious approach you can achieve high realism in PVD modeling.