Copyright © 2015-2025 Tin Model LLC. All rights reserved.

Approach PVD coating with precision:

try V-Grade 5S or V-Grade 5S Plus

- for the most challenging jobs

- for the most innovative ideas

- for the best thin-film products

V-Grade 5S Plus

A sputtering-centric numerical modeling tool set for PVD processes in a broad range of modalities and applications. It can be used to study and quantify such physical phenomena as desorption and re-sputtering of deposited material due to plasma-substrate interaction.

V-Grade 5S Plus is the most advanced and fastest tool set yet from us for PVD engineering.

V-Grade 5S

A versatile and comprehensive

modeling tool set for PVD in both evaporation and sputtering modes. Useful for achieving the best possible results through:

- Tooling & fixturing

- Thickness uniformity

- Material-collection efficiency

- Mask optimization

- Productivity

- Cost reduction

- and more....

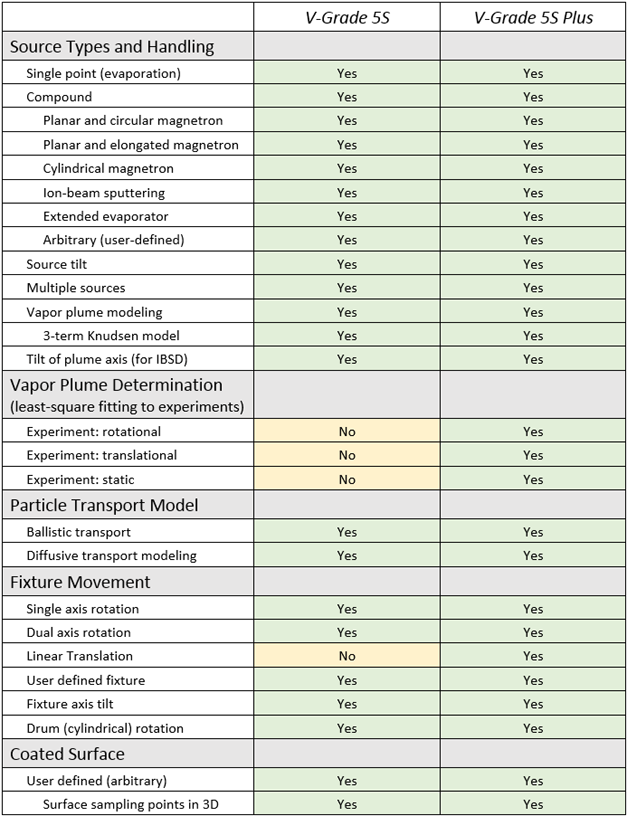

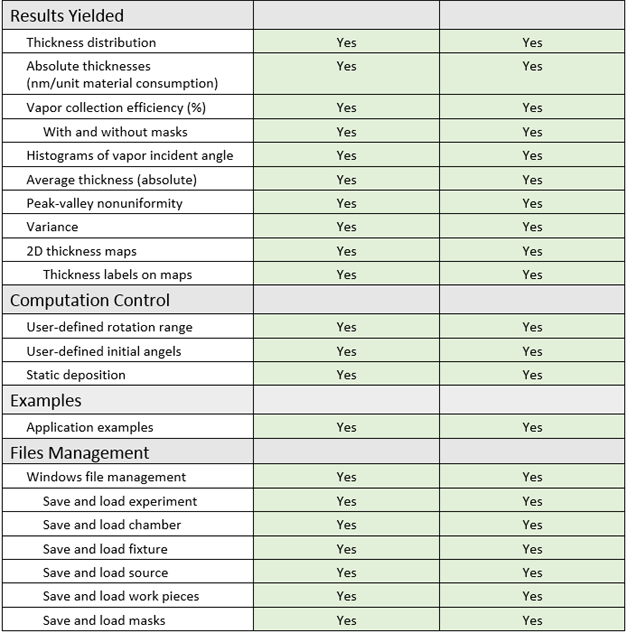

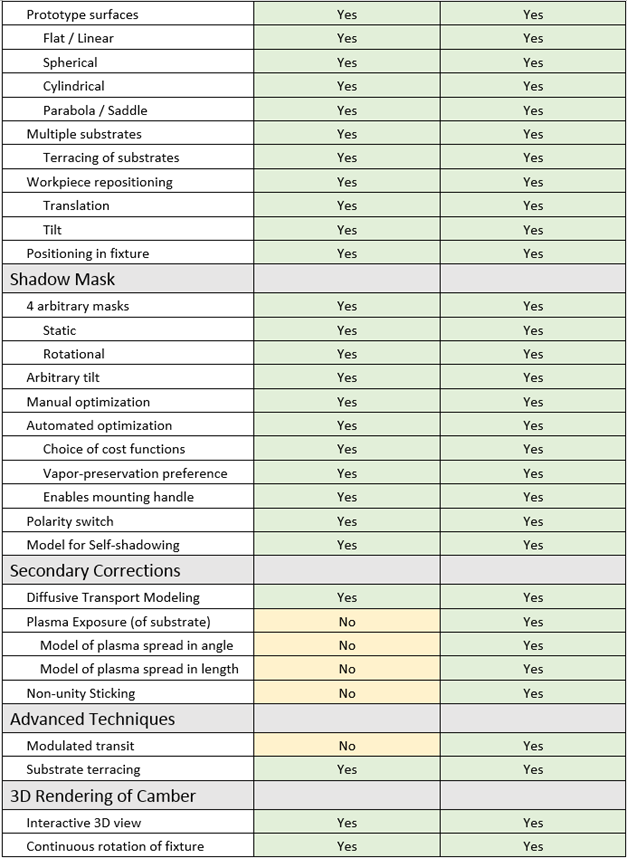

Comparison of Features

See features below

Tin Model LLC

V-Grade 5S Pro:

Engineering Tools of Our Time

Physical vapor deposition (PVD), as a manufacturing method, continues to grow in its applicability, from deep UV optics to giant telescope mirrors, from semiconductor-chip metalization to display panels. In step with the ever more challenging requirements in substrate types, coating precision and reduction in manufacturing cost, engineering of PVD processes must modernize to meet the tasks of our time.

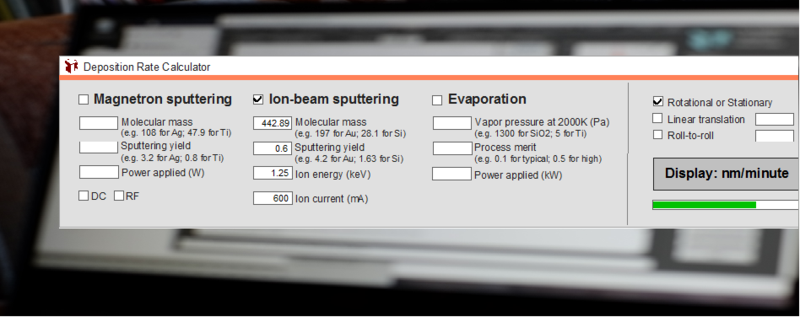

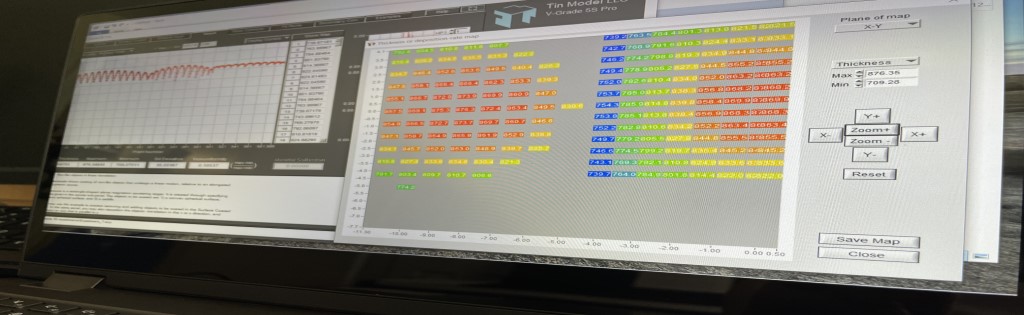

V-Grade 5S Pro is our answer to the needs of engineers and researchers in this field. V-Grade 5S Pro inherits the full functionality of its predecessors. New in V-Grade 5S Pro is a Deposition Rate Calculator (DRC). DRC seamlessly computes the deposition rate of any given material in any PVD process that you are investigating. With this new capability, V-Grade 5S Pro is complete in predicting and quantifying the three most important measures of a PVD process, namely:

Deposition rate -- for manufacturing throughput,

Vapor capture -- for cost of manufacturing, and

Thickness uniformity -- for meeting specifications of products.

V-Grade 5S Pro also provides you with a broad range of other information that you need in making engineering decisions, from an early conceptualizing phase to final optimization, in a PVD development cycle.

With the help of V-Grade 5S Pro you will be able to answer, in great certainty, some of the most difficult questions about a PVD process which may involve:

- E-beam evaporation

- Effusion-cell vapor sources

- Large-area evaporators

- Magnetron sputtering

- Ion-beam sputter deposition

- Unknown vapor plume

- Single-, dual- or triple-axis rotation tooling

- Tilt-planet fixtures

- Complex-surface substrates

- Roll-to-roll coating

- Ultra large substrates

- Rotatory cylindrical magnetron targets

- Arbitrary source configuration

- Arbitrary source movement

- Shadow masks

- Rotational masks

- Conformal coating of surface features

- High-aspect-ratio substrate features

- Baffles, including collimators

- Power-modulated transits

- Assistant ion bombardment

- Multi-source coating processes

- One-of-a-kind processes

- Diffusive transport

- HiPIMS

Let your creativity flow and turn your ingenuity to winning process designs.

V-Grade 5S Series Modeling Software

V-Grade 5S (Discontinued)

V-Grade 5S Plus (since 2018)

V-Grade 5S Pro (released 2021)

- Modality: sputtering, evaporation & ion-beam sputtering

- Partitioning walls

- All the above

- Deposition rates: sputtering, evaporation & ion-beam sputtering

- Source power requirement

- Process merit (including consumption of resources and environmental impact)

- Arbitrary source movement

- Arbitrary substrate movement

AVAILABLE FOR LICENSING